Chlor-Alkali Service

Solutions

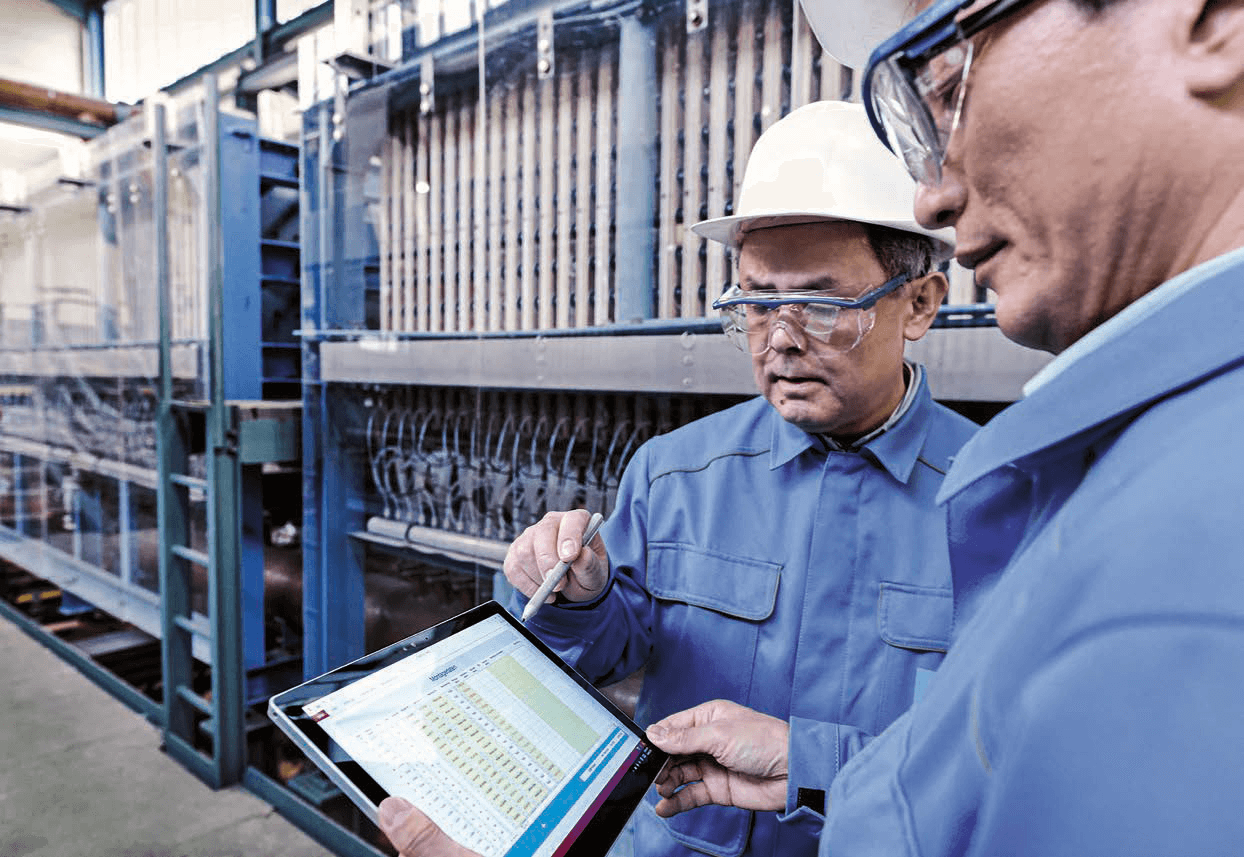

Your Partner Throughout the Entire Plant Lifecycle

We offer holistic service solutions for the entire lifecycle of your chlor-alkali plant – from commissioning to modernization. With thyssenkrupp nucera’s 360° Lifecycle Service, you receive tailored technical services designed to meet your specific needs. Our goal: maximum plant availability, top-tier safety, and optimal performance – worldwide.

Why Choose thyssenkrupp nucera?

Our 360° Chlor-Alkali Services are designed to precisely meet your individual requirements and help you in achieving a world-class plant performance. With a modular portfolio, we offer:

Technical Excellence & Fast Execution

Our services are tailored to your plant – ensuring maximum efficiency, availability, and reliability.True Partnership

Through close collaboration and continuous support, we build trust and ensure long-term success.Flexibility & Customization

Choose exactly the services you need – from targeted support to full-service solutions.Safety & Sustainability

We implement the highest HSE standards – aiming for zero accidents and maximum asset longevity.Our Service Portfolio

The lifecycle cost, performance, efficiency and safety of a plant strongly depend on the appropriateness of the service provided for each single component of the plant. Choose from our 13 specialized service products – individually or as a tailored package. Our experts support you with deep technical know-how and decades of industry experience.

Overview of Service Modules:

Sustain

nucera care

- Comprehensive and long-term for our customers throughout the entire plant lifecycle

- Fast access to experiences and know-how of thyssenkrupp nucera and its competence network

- Single point of contact for all relevant issues

nucera supply

- Highly qualified supply chain partner in OEM quality

- Certified and well tested components

- Ensure optimal cell performance

- Single point responsibility

- Prompt delivery by warehousing concept of key components

nucera maintain

Customized full-service maintenance projects executed by thyssenkrupp nucera completely with:

- Safety first – Zero accidents

- Experienced professionals

- Single point of responsibility

- Guaranteed schedule to minimize downtime

- New system guarantee

Staff

nucera diagnostics

- Evaluate the performance of the plant – on a regular basis or after an and make recommendations

- Effective problem-solving with root cause analysis

- Access to know-how of thyssenkrupp nucera and its competence network

- Early identification or prevention of issues

- Thus reducing power consumption and optimizing

nucera expertise

- Presence of thyssenkrupp nucera experts to site

- Immediate assistance to ensure quick, resolution and minimal downtime

- Skill development of the on-site team

- Sharing knowledge and best practices

nucera educate

- Refreshing the know-how of your engineers and operators

- Improve knowledge about technological fundamentals and operating procedures

- Identify risky operating practices

- Improve operating procedures

- Elevate safety levels, Reduce costs & downtime

nucera safety

- Plant Safety Review and HAZOP consulting services

- Expertise by thyssenkrupp nucera through valuable insights to improve plant safety

- Systematic approach to identify potential hazards and operability problems

- Improved operational safety by thyssenkrupp nucera

Revamp

nucera revamp

- Investigation studies to identify areas for improvemt

- Tailor-made plant revamps, engineering for customer’s chlorine plant

- Experienced revamp team for best practice solutions

- Lean project execution & lean cost

- Maximizing the profitability of plants with minimal conversion effort and shortest downtimes

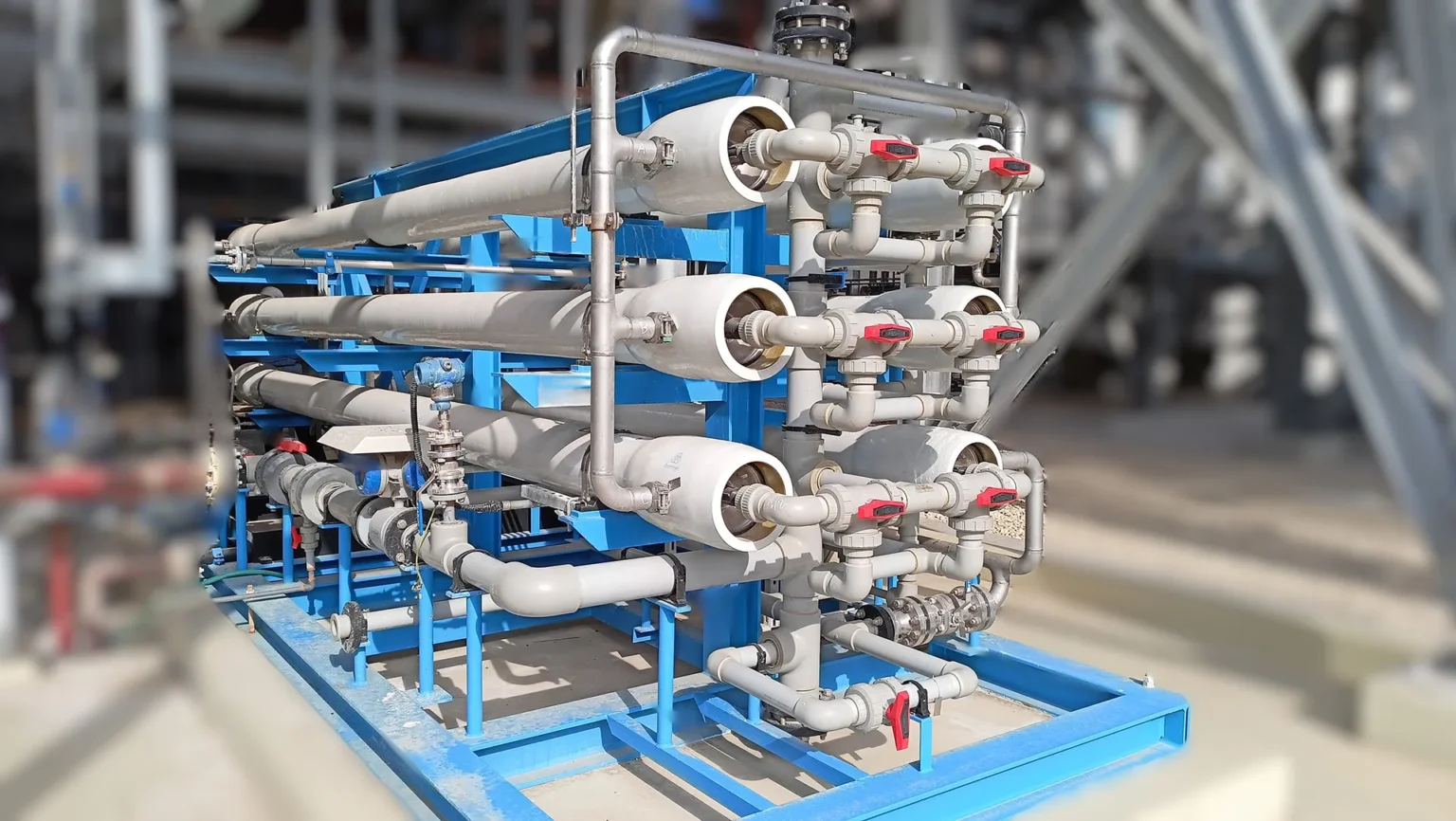

nucera SRU

Skid mounted Sulphate Removal Unit with

- Purge recovery for emission and OPEX reduction

- Minimization of liquid saline emissions

- Reduction of salt losses (8% – 9 %)

- Reduction of water losses (80% to 90%)

- Reduction of costs for liquid emissions

- Attractive ROI by saving salt and water

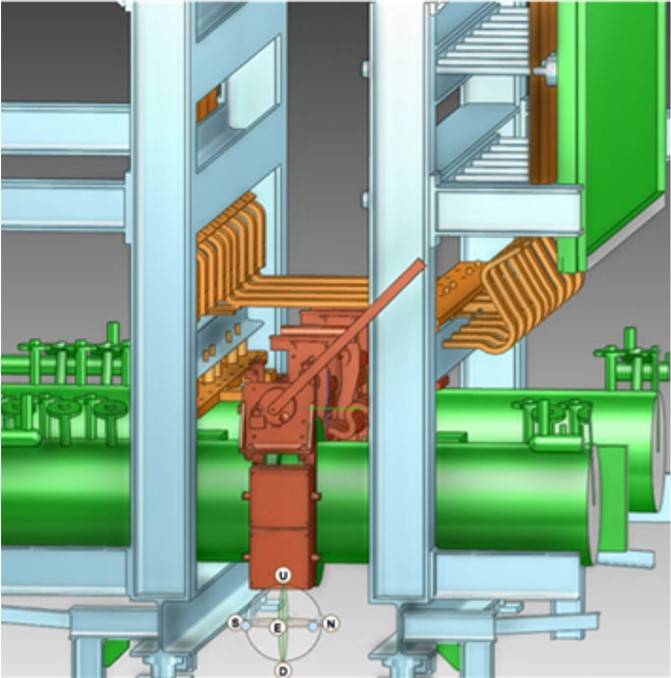

nucera EMS

- Electrolyzer Maintenance Switch (EMS) significantly enhances the safety and efficiency of electrolyzer maintenance by reducing the residual voltage to safe levels

- Ensuring electrical safety and integrating seamlessly into existing operating procedures

- Time reduction between draining and the start of maintenance activities reducing down time

nucera PipeTech

- Plastic and metal headers to ensure high quality and long service life

- Experienced PipeTech project team

- Lean project execution with single point of responsibility

- Long term material know-how and know-why for plastic and metallic piping

- PipeTech R&D with own test facility

Upgrade

nucera upgrade

- Upgrade to latest cell element generation

- Reaching power consumption less than 1,960 kWh / mt NaOH 100%

- Experienced revamp project team

- Start of a new product lifecycle

- Improved product quality

- Higher plant availability

- Lower repair & maintenance cost

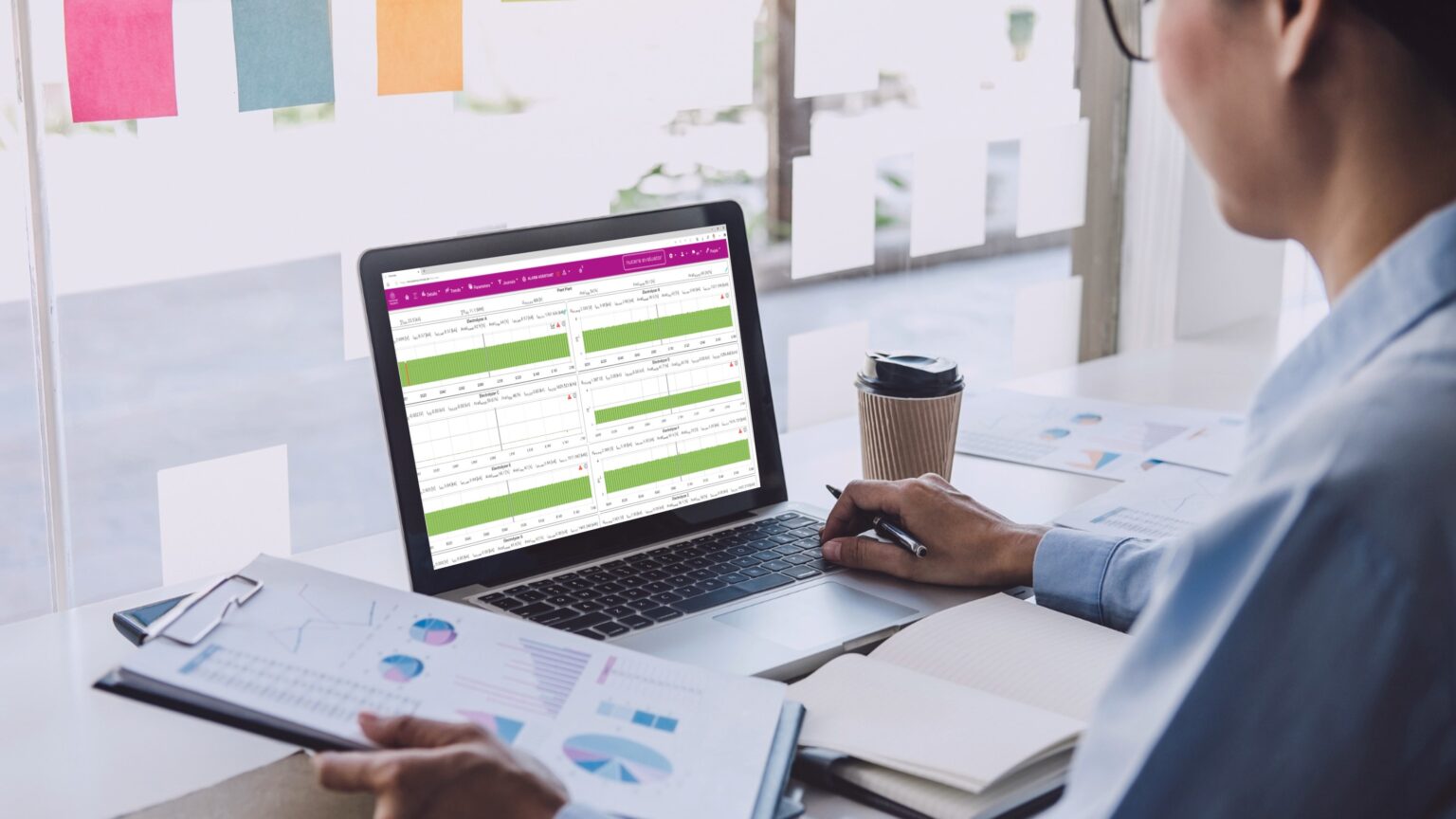

Digital

nucera evaluator system

- Protection of the customers’ assets by

- Cell Voltage Monitoring system (CVMS)

- Insulation Monitoring System (IMS)

- Busbar Symmetry Monitoring System (BSM)

- On Demand start-up support

- Performance analysis by UI-Curve wizard

- Cell element administration

- Safeguard functions, SIL 2 and ex-zone possible